10 Best Aluminum Welders 2026 in the United States

Winner

ARCCAPTAIN 250A MIG Welder, 110V 220V Gas MIG/Gasless MIG/Stick/Lift TIG/Spool Gun/Spot 6 in 1 Welding Machine Aluminum Welding Machine Professional Welder Machine with Large LED Display

The ARCCAPTAIN 250A MIG Welder is a versatile aluminum welding machine designed to handle a variety of welding tasks. It offers six different welding modes, including Gas MIG, Flux Core MIG, Lift TIG, MMA, Spot, and Spool Gun. This makes it a great choice for those who require flexibility in their welding projects, whether working with mild steel, carbon steel, stainless steel, or aluminum. However, it is important to note that the Lift TIG torch and Spool Gun are sold separately, which could be a consideration for those on a budget.

Most important from

1062 reviews

Miller 907757 Multimatic 220 AC/DC Multiprocess Welder - Versatile Multi-Process MIG, Flux-Cored & TIG Welder Machine - Portable Welding Machine with MIG Gun, TIG Torch & Multi-Voltage Plug 120V&240V

The Miller 907757 Multimatic 220 AC/DC Multiprocess Welder offers a versatile welding solution, allowing you to tackle various welding processes including MIG, flux-cored, Stick, and TIG with one machine. This all-in-one capability makes it an excellent choice for users who need flexibility in their welding projects. The intuitive QuickTech feature simplifies the welding setup by automatically determining the correct polarity and process, and recalling your last settings, which saves time and reduces manual adjustments.

Most important from

44 reviews

Millermatic 211 PRO MIG Welder Machine - Dual-Voltage Portable Flux Core Welder with Auto-Set & Spool Gun Detection - Aluminum, Mild & Stainless Steel Welding Machine - Wire Feed Gas Welder

The Millermatic 211 PRO MIG Welder is a flexible and user-friendly machine ideal for those who need to weld aluminum, mild steel, and stainless steel with ease. It supports flux core and gas shielded welding, making it versatile for different projects. One of its standout features is the built-in spool gun detection, which automatically adjusts settings when welding aluminum, a big help if you're switching between metals.

Most important from

10 reviews

Top 10 Best Aluminum Welders 2026 in the United States

Winner

ARCCAPTAIN 250A MIG Welder, 110V 220V Gas MIG/Gasless MIG/Stick/Lift TIG/Spool Gun/Spot 6 in 1 Welding Machine Aluminum Welding Machine Professional Welder Machine with Large LED Display

ARCCAPTAIN 250A MIG Welder, 110V 220V Gas MIG/Gasless MIG/Stick/Lift TIG/Spool Gun/Spot 6 in 1 Welding Machine Aluminum Welding Machine Professional Welder Machine with Large LED Display

Chosen by 1108 this week

Miller 907757 Multimatic 220 AC/DC Multiprocess Welder - Versatile Multi-Process MIG, Flux-Cored & TIG Welder Machine - Portable Welding Machine with MIG Gun, TIG Torch & Multi-Voltage Plug 120V&240V

Miller 907757 Multimatic 220 AC/DC Multiprocess Welder - Versatile Multi-Process MIG, Flux-Cored & TIG Welder Machine - Portable Welding Machine with MIG Gun, TIG Torch & Multi-Voltage Plug 120V&240V

Millermatic 211 PRO MIG Welder Machine - Dual-Voltage Portable Flux Core Welder with Auto-Set & Spool Gun Detection - Aluminum, Mild & Stainless Steel Welding Machine - Wire Feed Gas Welder

Millermatic 211 PRO MIG Welder Machine - Dual-Voltage Portable Flux Core Welder with Auto-Set & Spool Gun Detection - Aluminum, Mild & Stainless Steel Welding Machine - Wire Feed Gas Welder

ARCCAPTAIN TIG Welder AC/DC 200Amp with Pulse, Aluminum TIG Welder 110V/220V TIG Welder with Square/Triangular Wave/Stick/MMA/Spot 7 in 1 MultiProcess Welding Machine

ARCCAPTAIN TIG Welder AC/DC 200Amp with Pulse, Aluminum TIG Welder 110V/220V TIG Welder with Square/Triangular Wave/Stick/MMA/Spot 7 in 1 MultiProcess Welding Machine

YESWELDER MIG-205DS PRO MIG Welder, 200Amp 110/220V Dual Voltage MIG Welding Machine, 5 in 1 Gas MIG/Flux Core MIG/Spool Gun MIG/Lift TIG/Stick Multiprocess Aluminum MIG Welder, Spool Gun Compatible

YESWELDER MIG-205DS PRO MIG Welder, 200Amp 110/220V Dual Voltage MIG Welding Machine, 5 in 1 Gas MIG/Flux Core MIG/Spool Gun MIG/Lift TIG/Stick Multiprocess Aluminum MIG Welder, Spool Gun Compatible

Miller Millermatic 252 Electric MIG Welder, Wheeled, 208/230VAC (907321)

Miller Millermatic 252 Electric MIG Welder, Wheeled, 208/230VAC (907321)

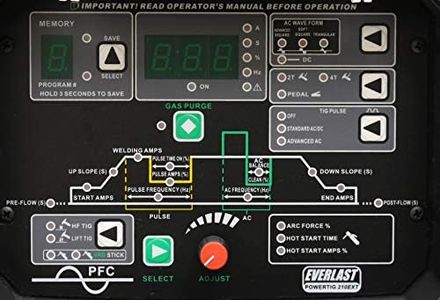

Everlast PowerTIG 255EXT Digital AC/DC TIG Stick Pulse Inverter Welder 110v/220v Dual Voltage

Everlast PowerTIG 255EXT Digital AC/DC TIG Stick Pulse Inverter Welder 110v/220v Dual Voltage

ESAB® Renegade VOLT™ ES 200i Battery-Powered Stick and TIG Welder

ESAB® Renegade VOLT™ ES 200i Battery-Powered Stick and TIG Welder

Lincoln Electric 90i MIG and Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5256-1

Lincoln Electric 90i MIG and Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5256-1

Everlast PowerTIG 210EXT 210Amp Ac Dc Tig Stick Advance Pulse Welder 110/220 Volt Inverter-Based IGBT Technology

Everlast PowerTIG 210EXT 210Amp Ac Dc Tig Stick Advance Pulse Welder 110/220 Volt Inverter-Based IGBT Technology

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.